Let’s talk about T-shirts. Or circuit boards. Or steel components. Whatever it is your business produces, chances are you’ve already considered outsourcing some part of it. And if you haven’t, you’re probably burning more time and money than you need to.

Outsourcing manufacturing isn’t only there to save money and resources. It’s strategic. It gives your business the chance to speed up production, stay flexible, and gain access to global skills.

For many companies, it’s been the quiet force behind their ability to scale quickly and stay focused.

Some of the most successful brands, Apple, Nike, and countless others, rely on outsourced manufacturing not because they lack resources, but because they know their time and energy are better spent elsewhere.

This guide is for businesses at a crossroads. You might be scaling fast, launching a new product line, or just tired of equipment maintenance and staffing headaches.

Whatever your reason, outsourcing manufacturing might just be your smartest next move.

Outsourcing Manufacturing Guide: Overview & SectionsTable of Contents

- What is Outsourcing Manufacturing?

- Why Manufacturing In-House Isn’t Always Optimal

- Benefits of Outsourcing Manufacturing

- Common Misconceptions When Manufacturers Outsource

- Your To-Do List on How to Outsource Manufacturing

- Get Started with Manufacturing Outsourcing

- FAQs

What is Outsourcing Manufacturing?

Outsourcing manufacturingmeans working with external companies to produce your goods instead of making everything in-house. It’s one of the oldest forms of outsourcing in modern business.

Back in the 1970s and 1980s, companies in the US and Europe started shifting production overseas(offshoring) to take advantage of lower labour costs. This allowed them to stay competitive without compromising quality.

Over time, the model evolved. What began as cost-cutting became a way to access specialised skills and new technologies.

Today, outsourcing means forming strategic partnerships. Businesses in the know consider it a way to work with experts who can deliver faster, better, and with fewer headaches.

Why Manufacturing In-House Isn’t Always Optimal

Owning a production line can feel like control. You see your products being made in real time. You know your team. But behind that pride is a long list of hidden costs and risks.

Setting up internal manufacturing requires a serious capital commitment. Machinery, real estate, and a specialised workforce are just the start. Then come maintenance costs, training expenses, and constant upgrades.

Scaling is also a challenge. If demand increases suddenly, you may not have the capacity to meet it. If demand drops, you’re left with expensive idle equipment.

Another issue is staying up to date. Manufacturing today isn’t static. Technology evolves. Materials change. Standards tighten. And unless you’re a manufacturing company at heart, keeping up takes time and attention away from what your business mainly does.

Benefits of Outsourcing Manufacturing

Outsourcing manufacturing offers significant benefits:

Cost Efficiency

By outsourcing, you eliminate the need to invest in expensive equipment or pay for full-time staff when you don’t have consistent demand.

This frees up capital for other parts of your business, like marketing or product development. You also reduce maintenance, utilities, and overhead costs.

A well-chosen manufacturing partner often delivers the same product at a lower price point without sacrificing quality.

2. Scalability

When you outsource, you can scale production quickly. No need to buy new machines or train more staff. This is especially helpful during seasonal demand spikes or new product launches.

3. Speed to Market

Established manufacturers have the infrastructure to move fast. They’ve already ironed out supply chain wrinkles and logistics. That means you can go from prototype to shelf in a fraction of the time.

In competitive industries, that speed can make or break your product’s success.

4. Focus on Core Competencies

You probably didn’t start your business to manage factories. Outsourcing lets you shift energy back to product design, customer experience, and strategy.

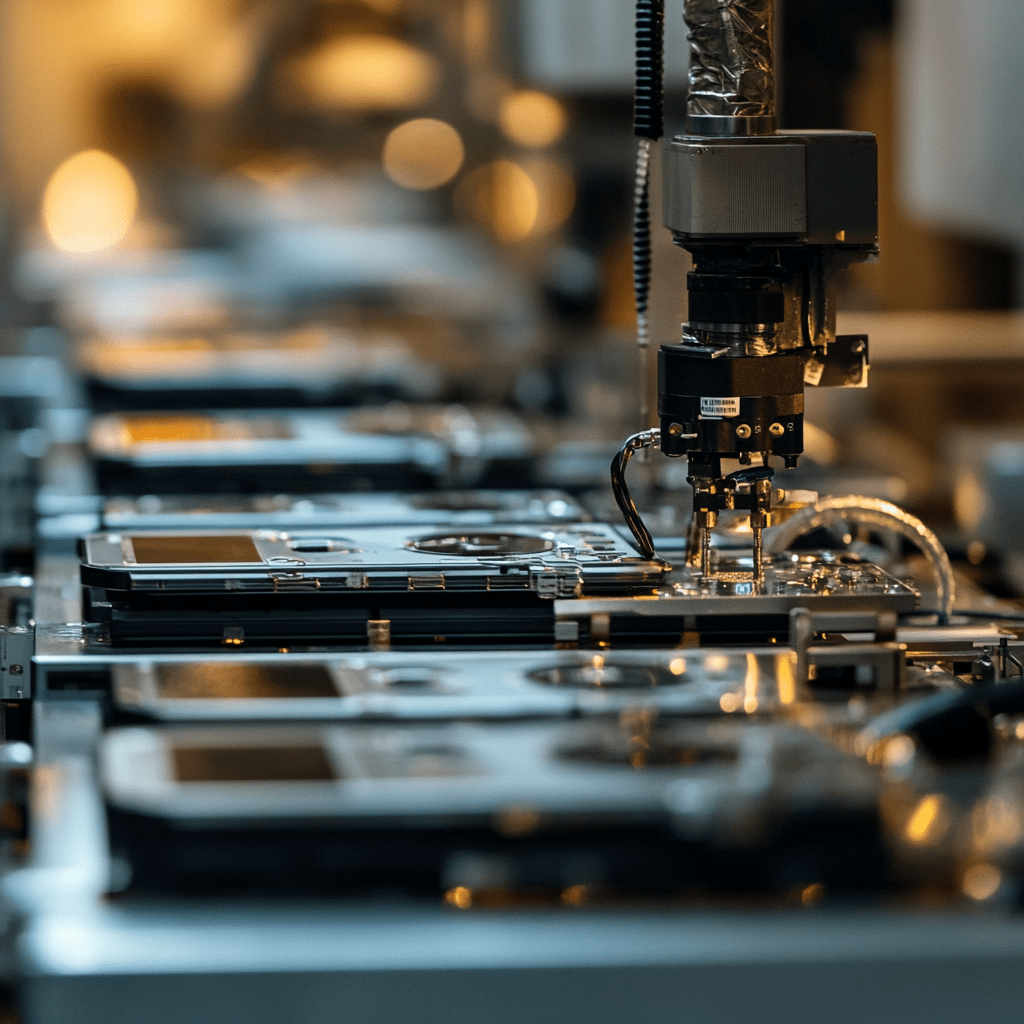

5. Access to Expertise and Technology

Not all businesses can afford cutting-edge machinery or highly specialised teams. But outsourcing levels the playing field.

You get access to innovations and skill sets that would otherwise be out of reach. This can improve product quality and open the door to advanced manufacturing techniques.

6. Lower Risk

By partnering with manufacturers in different regions or industries, you spread your risk. But if one facility goes down due to political unrest, a pandemic, or a natural disaster, you’re not completely out of luck. Diversification gives you options.

Common Misconceptions When Manufacturers Outsource

Despite its widespread adoption and clear benefits, outsourced manufacturing still carries certain misconceptionsthat can deter businesses from exploring its potential:

Misconception #1: “Quality will suffer.”

Some believe outsourcing, especially offshoring, equals subpar products. That’s not always true. Many outsourced manufacturers operate under strict quality standards.

In some cases, their quality control processes are more refined than those of internal teams. What matters most is finding the right partner and setting clear expectations.

Misconception #2: “I’ll lose control over my product.”

Control doesn’t vanish when you outsource. It just changes. Instead of daily management, you use contracts, KPIs, and audits to ensure everything stays on track.

Transparency and communication bridge the gap. With the right tools and relationships, control can even improve.

Misconception #3: “It takes away jobs from home.”

It’s understandable to worry about jobs potentially moving overseas. While some production work might indeed shift, offshoring, in this case, often allows the main business to expand at a faster pace.

This expansion can then open up new, higher-value roles right where you are. Think of areas like research, product design, marketing, sales, and strategic leadership.

What we often see is resources being redirected towards activities that genuinely drive long-term company growth and create other job opportunities within the business.

Misconception #4: “Outsourcing is only for big companies.”

In fact, smaller businesses can benefit the most. For startups and SMEs, outsourcing reduces the barrier to entry. You don’t need millions in capital to start producing. You just need a solid idea and a reliable partner.

Misconception #5: “It’s all or nothing.”

You don’t have to outsource your entire operation. You can start small.

Outsource a single product line or phase, like assembly or packaging, and expand as needed. Many businesses use a hybrid modelto balance control and cost.

Your To-Do List on How to Outsource Manufacturing

Outsourcing manufacturing requires a structured approach to ensure success. Here are some tips on how to get started on it:

✔ Define Your Needs. Before anything else, clarify what you want to outsource. List product specs, materials, quality standards, and timelines.

The clearer you are, the better your partner can deliver. Vagueness leads to mistakes.

✔ Research Potential Partners. Look for manufacturers with experience in your industry. Read reviews, request samples, and talk to past clients. Ask about their certifications and how they handle issues.

✔ Ask the Right Questions. What happens if something goes wrong? How do they ensure quality? What’s their track record with deadlines? A good partner welcomes tough questions.

✔ Start with a Trial Order. Test runs reveal a lot. They show how well the partner communicates, handles quality checks, and sticks to deadlines. It’s a small investment to prevent big problems later.

✔ Protect Your IP. Make sure your contracts include confidentiality clauses and define who owns what. If needed, seek legal guidance and register your IP in the partner’s country.

✔ Plan Logistics and Inventory. Manufacturing is only half the story. You still need to get products to customers. Coordinate shipping, storage, and customs. Think about time zones, holidays, and lead times.

✔ Communicate Constantly. Great outsourcing relationships are built on communication. Share updates. Give feedback. Ask questions. A responsive partner is usually a reliable one.

Get Started with Manufacturing Outsourcing

Bringing a product to life, from sketch to shelf, is a high-stakes process filled with moving parts.

When production starts pulling your focus away from strategy, marketing, and innovation, something needs to shift.

Working with an experienced manufacturing partner gives your ideas room to breathe and grow. And with the right team behind you, your business can run leaner, move faster, and scale with less friction.

FAQs

What industries commonly use manufacturing outsourcing?

Industries like electronics, fashion, automotive, and consumer goods have long embraced manufacturing outsourcing. It allows them to stay competitive while focusing on innovation, brand development, and customer relationships.

Even heavily regulated sectors like medical devices and aerospace work with external manufacturers. The key is choosing partners who understand and meet industry-specific compliance requirements.

Is outsourcing manufacturing only for overseas production?

Not at all. While many companies choose to outsource overseas for cost reasons, domestic outsourcing is also common. Local manufacturers can offer faster turnaround, simpler logistics, and easier collaboration.

Your decision should depend on priorities like budget, speed, quality, and location of your customer base.

What is the difference between outsourcing manufacturing and contract manufacturing?

These terms are often used interchangeably. Outsourcing manufacturing describes the general practice, while “contract manufacturing” specifically refers to the third-party company you hire to produce goods under a contract.

How do I protect my intellectual property when outsourcing manufacturing?

You protect intellectual property through robust non-disclosure agreements (NDAs) and comprehensive IP clauses in your manufacturing contract.

Like for many other concerns, the key is choosing a reputable outsourcing provider.